Revolutionizing Indoor Sensor Power: Rapid Microwave Annealing for Ultra-low-cost Perovskite Solar Cells

The Challenge

Sensors are traditionally powered by batteries that generate toxic waste upon disposal. According to the CSIRO, the rate of lithium-ion battery waste in Australia is escalating at an alarming rate of 20 percent annually, with projections suggesting it could surpass 100,000 tonnes by 2036. Yet a mere 2 percent of the country's annual 3,300 tonnes of lithium-ion battery waste undergo recycling. The situation is even more critical for alkaline batteries; every year, approximately 264 million handheld batteries reach their end of life, and less than 5 percent are recycled. Millions of these batteries are used in smart sensors and data loggers, which contribute to this problem.

The Solution

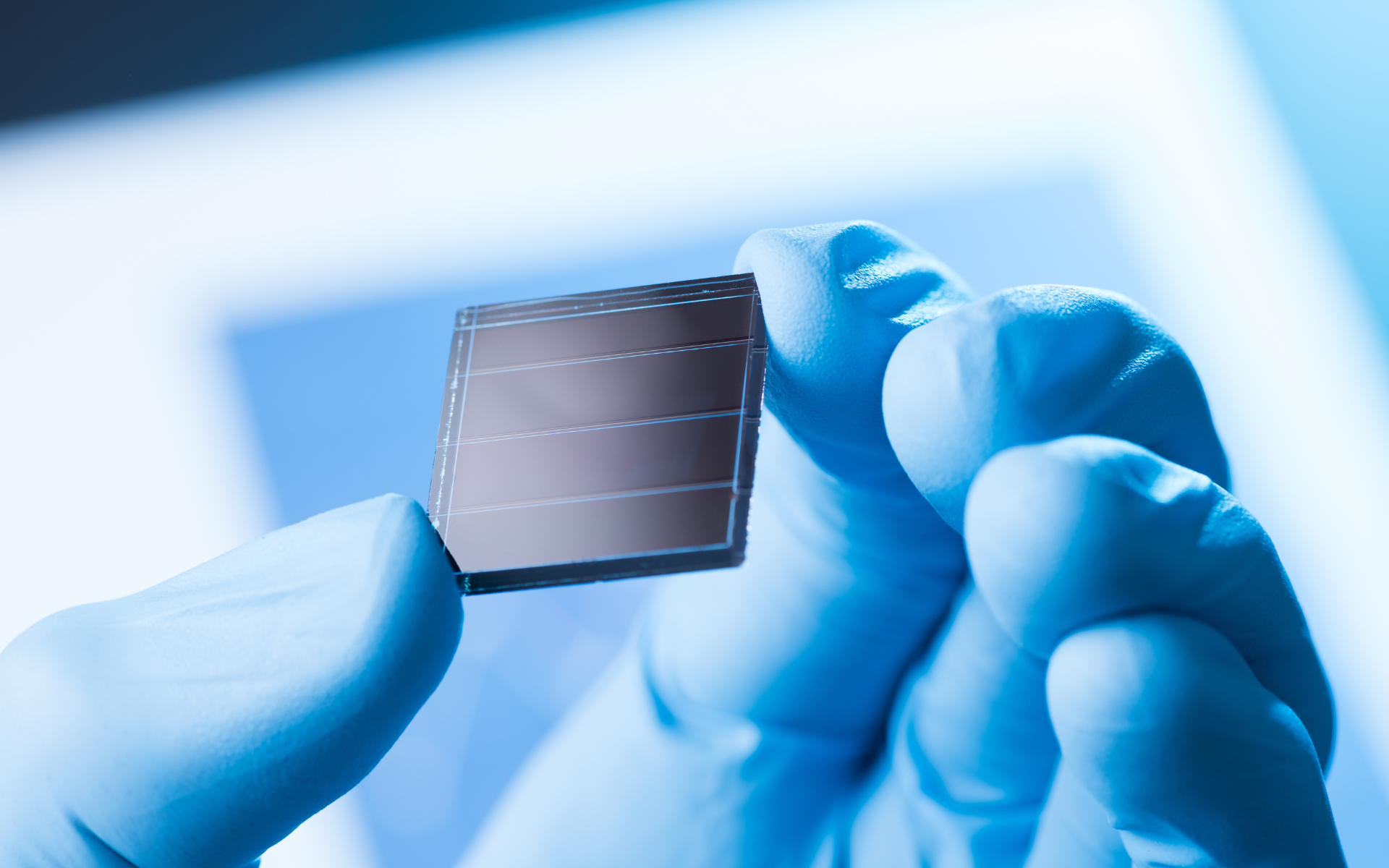

This project facilitates a sustainable alternative using photovoltaic (PV) cells, specifically perovskite PV cells, optimized for indoor lighting. Perovskite cells offer continuous power, ideal for low-power sensors. While cost-effective and suitable for roll-to-roll fabrication, their widespread adoption is slowed down by the lengthy annealing time required. This project significantly speeds up this process by 300 percent using microwave annealing. This rapid method not only accelerates production but also enhances cell quality. The goal of the project is to demonstrate the feasibility of this technique in roll-to-roll manufacturing, paving the way for large-scale, eco-friendly indoor sensor deployment. This innovation will eliminate the reliance on disposable batteries, marking a significant step in sustainable innovation.